Chain conveyors

JEMA conveyors can easily be fitted into any conveying installation

JEMA conveyors are made of a strong galvanized material, which makes them particularly suitable for outdoor applications. Conveyors are designed for transportation of grain and other bulk goods. A quality roller chain fitted with rubber or synthetic carriers ensures that all material transport is conducted quietly, safely and effectively.

Conveyors work in a horizontal position and with an upward curve. They’re efficient in both versions and have a low power consumption in relation to their capacity.

All parts are made with a CNC machine, so they all fit perfectly into each other. As a result, installation is simple. The manufacturer has pre-set 40% of it’s maximum output.

MateriaLS

| conveyor | T44 | T45 | T49 | T57 |

|---|---|---|---|---|

| Capacity based on 750 kg/m3 (wheat) [t / h] | 30 | 60 | 105 | 150 |

| Capacity [m3 / h] | 40 | 80 | 140 | 200 |

| RPM [1 / min] | 180 | 180 | 45 / 60 | 45 / 60 |

| Chain speed [m / s] | 1,1 | 1,1 | 0,79 / 0,99 | 0,79 / 0,99 |

| Chain length [mm] | 41,4 | 41,4 | 125 | 125 |

| Tensile strength (dyn.) [kN] | min. 17,8 | min. 17,8 | 118 | 118 |

| Carrier material | rubber | rubber | PEHD 1000 | PEHD 1000 |

| Thickness: drive station [mm] | 3 | 3 | 3 | 3 |

| Thickness: tightening section [mm] | 3 / 1,5 | 3 / 1,5 | 3 | 3 |

| Thickness: other parts [mm] | 1,5 | 1,5 | 3 | 3 |

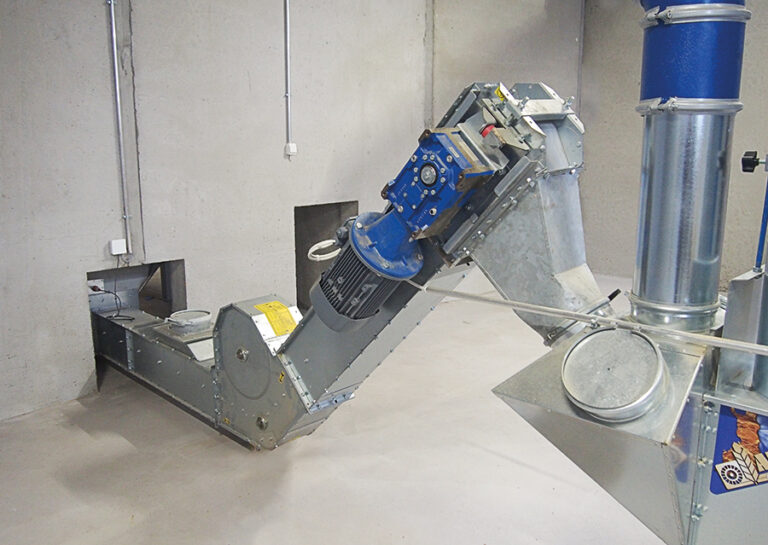

T44/T45 Intake conveyors

standard equipment

- Directly mounted gear motor

- Torque arm for shock absorption

- 90° outlet hopper in drive station

- Tensioner, inspection and cleaning hatches in drive station and tightening section

- Adjustable plates in the inlet troughs

options

- Power transmission with V-belts

- 45° upward curve

- Tipping hopper

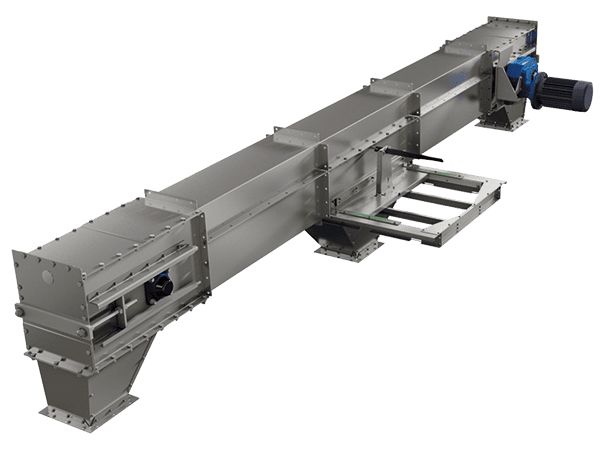

T49/T57 Horizontal conveyors

standards equipment

- Directly mounted gear motor

- Outlet hopper in drive station

- Inspection hatch in drive station and tightening section

- Inlet

options

- Intermediate outlet

- Shutter in drive station / tightening section

- Wire suspension

- Speed control

Fair warranties

8 years

Heat exchangers

5 years

Grain dryers

5 years

Silos

5 years

Elevators

1 year

Electrical parts